Sale!ASTM A519 1026 Precision ID H8 Hydraulic Cylinder Honed Tube from Chinese supplier

| Grade | C | Si | Mn | P | S | Cr | Mo |

|---|---|---|---|---|---|---|---|

| 1026 | 0.22-0.28 | / | 0.60-0.90 | 0.040 max | 0.050 max | / | / |

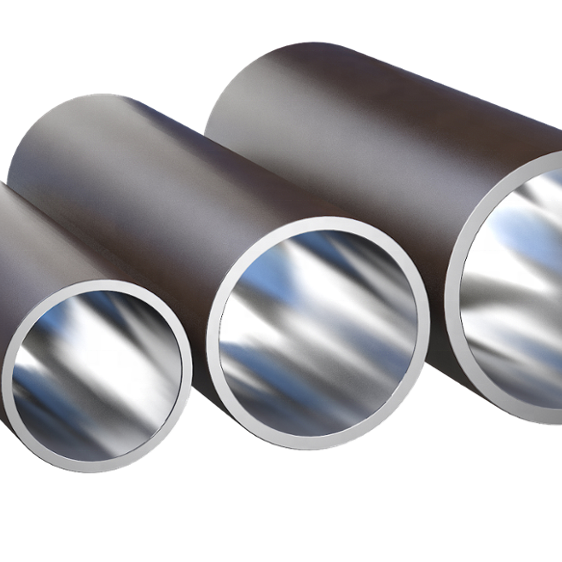

Description:

Our honed tube is produced using our Suitable To Hone Drawn Over Mandrel (DOM) and Cold Drawn Seamless CDS. This honed tube is ready to use for hydraulic cylinder applications without further ID processing.

The honing process involves using abrasive polishing stones and abrasive paper to remove small amounts of material, to produce extremely precise ID dimensions and improved finishes.

Application:

Hydraulic Cylinder, Hydraulic Jack, hydraulic oil cylinder pneumatic cylinder, petrifaction oil pump, coal mine, engineering machinery, crane and transport machinery, auto transmission axes, plastic machinery, engineering machinery, crane and transport machinery, auto transmission axes, plastic machinery, hydraulic oil cylinder, pneumatic cylinder, absorber, spin printing and dyeing.

Main Features:

1. Roughness(Ra) can be 0.08µm or less.

2. Ovality can be 0.01 mm or less.

3, Hardness can be HV4° or higher.

Sizes Range:

Inner Diameter: 12-1100mm

Wall Thickness: 2~55mm

Max Length: 12 meters

Dimension Tolerance:

| Processing Way | Cylinder Barrel ID (mm) | Max Length (mtr) | Straightness (mm/mtr) | ID Tolerance | Wall Thickness Tolerance (mm) | ID Roughness (μm) |

|---|---|---|---|---|---|---|

| Cold Drawn | 40-320 | 12 | 0.2-0.5 | H8-H10 | ±5% | 0.8-1.6 |

| Cold Rolled | 12-100 | 12 | 0.2-0.5 | H8-H10 | ±5% | 0.8-1.2 |

| Cold Drawn+Honed | 40-500 | 8 | 0.2-0.3 | H7-H9 | ±5% | 0.2-0.8 |

| Cold Drawn-SRB | 40-400 | 7 | 0.2-0.3 | H8-H9 | ± 5% | 0.2-0.4 |

| Deepth Drilling-Honed | 320-1100 | 8 | 0.2-0.3 | H7-H9 | ±8% | 0.2-0.8 |

| Deepth Drilling-SRB | 320-600 | 7 | 0.2-0.3 | H8-H9 | ±8% | 0.2-0.4 |

Process:

Raw materials- Cold drawn/rolled- Heat treatment (BKS)- Honed or SRB- packing.

Standard and Optional Testing:

Visual and dimensional test 100%.

Eddy current test 100% acc. to EN 10246-3.

Ultrasonic test 100% acc. to EN 10246-7.

Chemical composition.

Impact test.

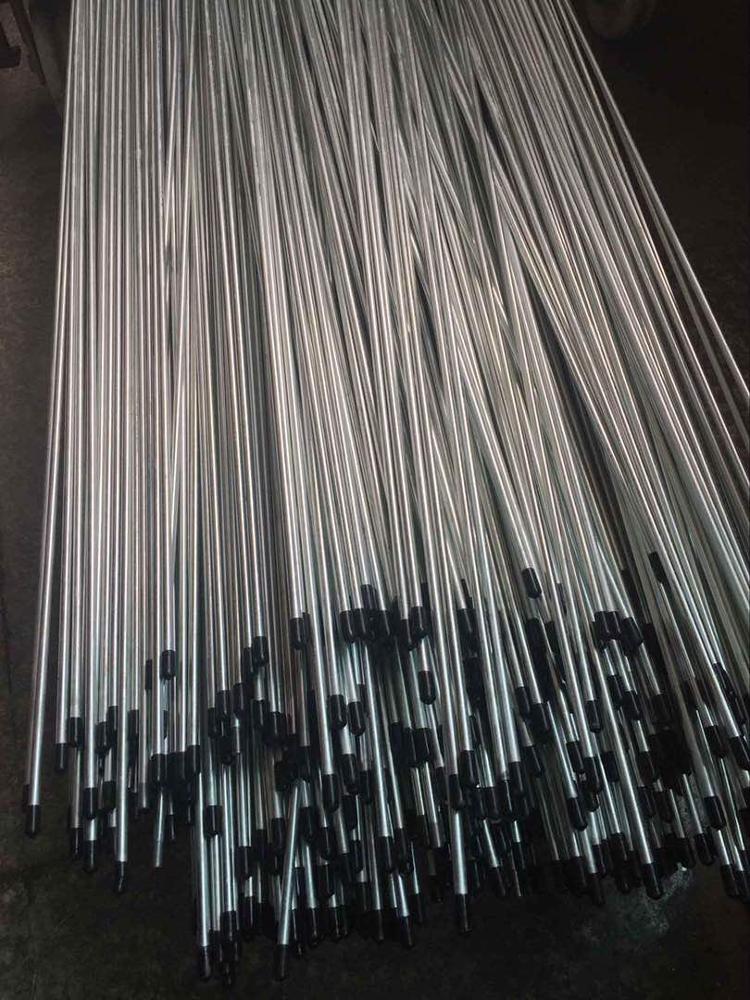

Package:

1. Bundle Packing.

2. Plain end or vanished as per customer’s request.

3. Wrapped in waterproof paper.

4. Sackcloth with several steel strips.

5. Pack in heavy tri-wall boxes.

Mill Test Certificate:

The product is supplied with 3.1.B inspection certificate,according to the standards EN 10204 and ISO 10474.

Our Services:

Third Party inspection acceptable. such as SGS, BV etc.

Supplying financial support with usance L/C 180 days after B/L date.